Earlier this year we received news that Birmingham based interior and architectural design studio SCULPT, in collaboration with STEAMhouse, a local center for creative innovation was developing an installation made of DISPA® with the goal of testing DISPA’s capabilities and unique properties.

DISPA® consists of a patented embossed formed paper core that is laminated on both sides with bright white, smooth paper surfaces – a unique composition that makes this paper board lightweight yet extremely rigid, strong and dimensionally stable. Signs created with lightweight DISPA® stay flat yet are easy to handle and hang. Manufactured with 100 percent Forest Stewardship Council® (FSC®)-certified paper (FSC®-C169891), DISPA® is fully recyclable. (The FSC® is a nongovernmental organization operating in more than 80 countries to facilitate responsible forest management in accordance with social, economic and ecological needs.)

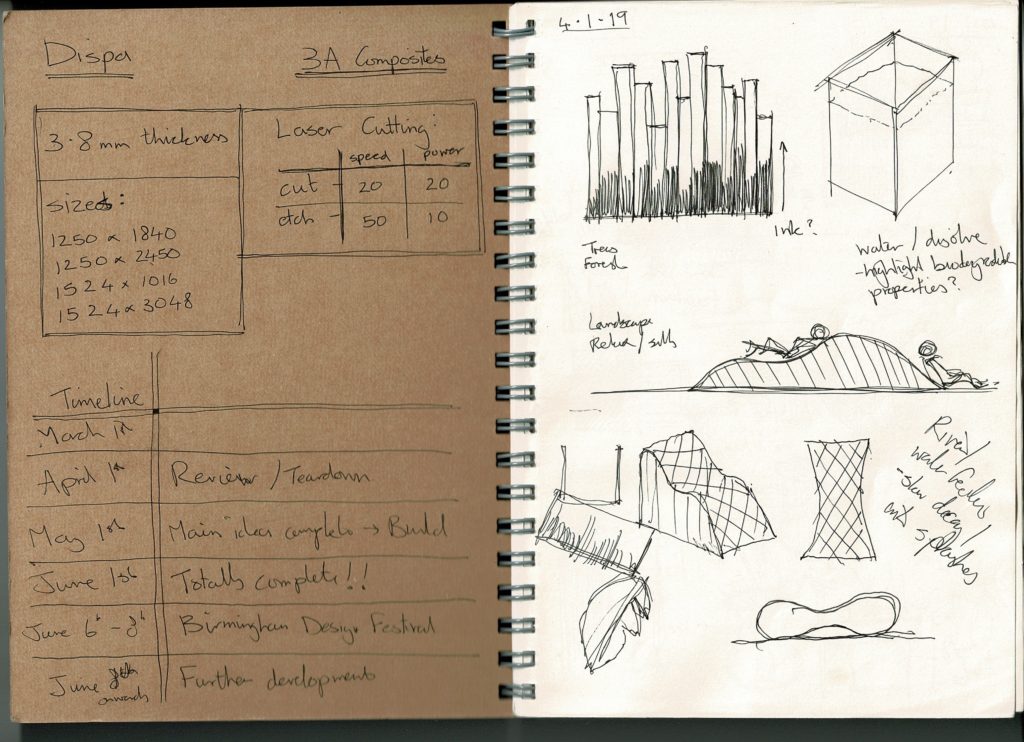

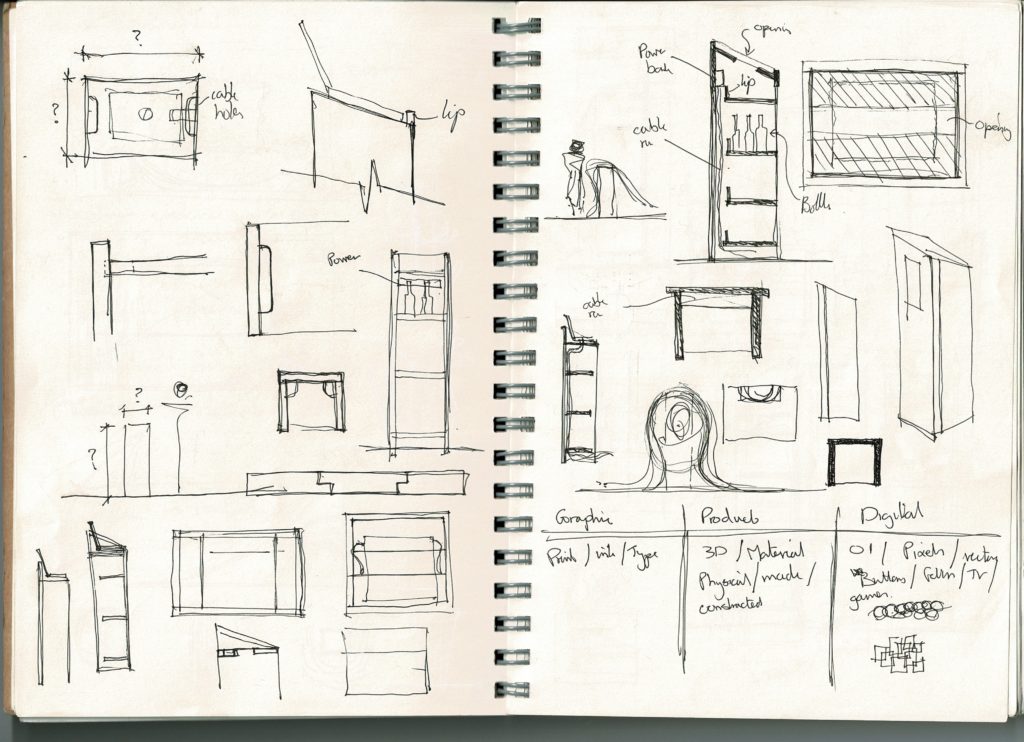

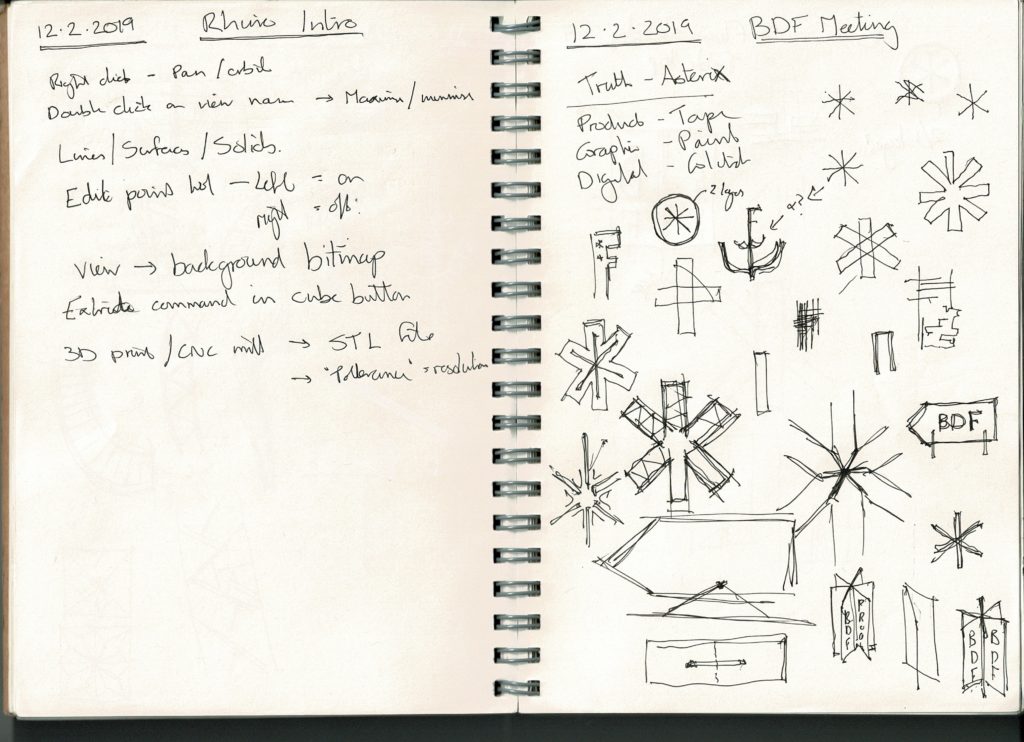

After months of anticipation the installation was revealed at the 2019 Birmingham Design Festival. The festival aims to provide an affordable immersive experience in three distinct ‘Districts’ of design: Graphic, Digital, and Product. The theme for 2019 was “Truth”, building on this, Ash Wilson, Creative Director, SCULPT, developed the installation titled, “Confession”.

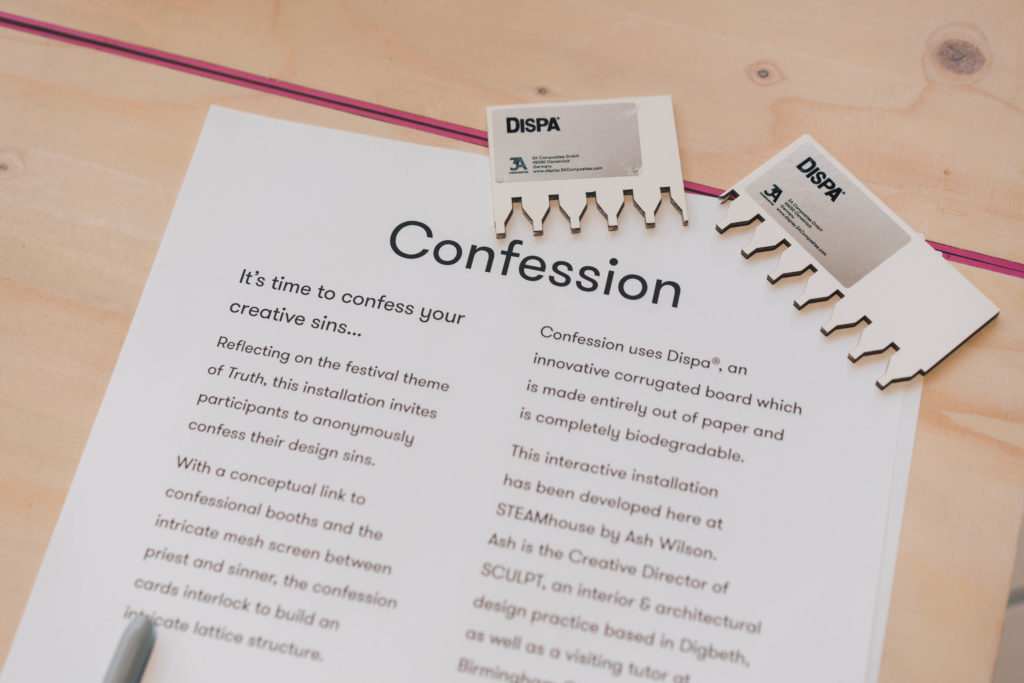

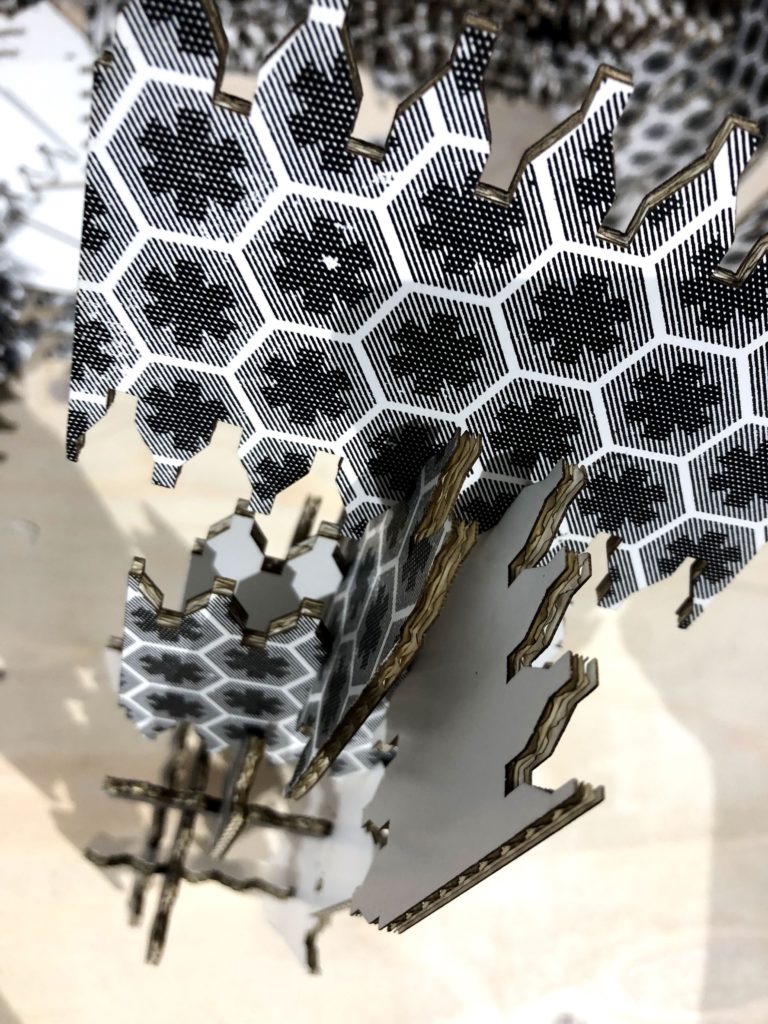

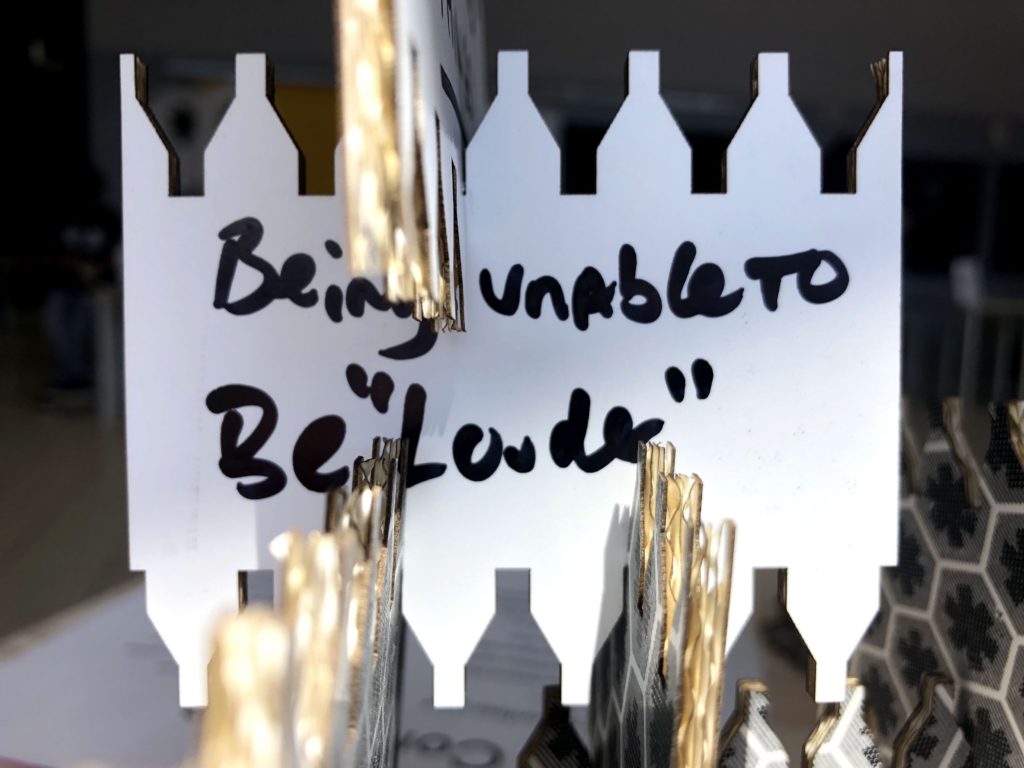

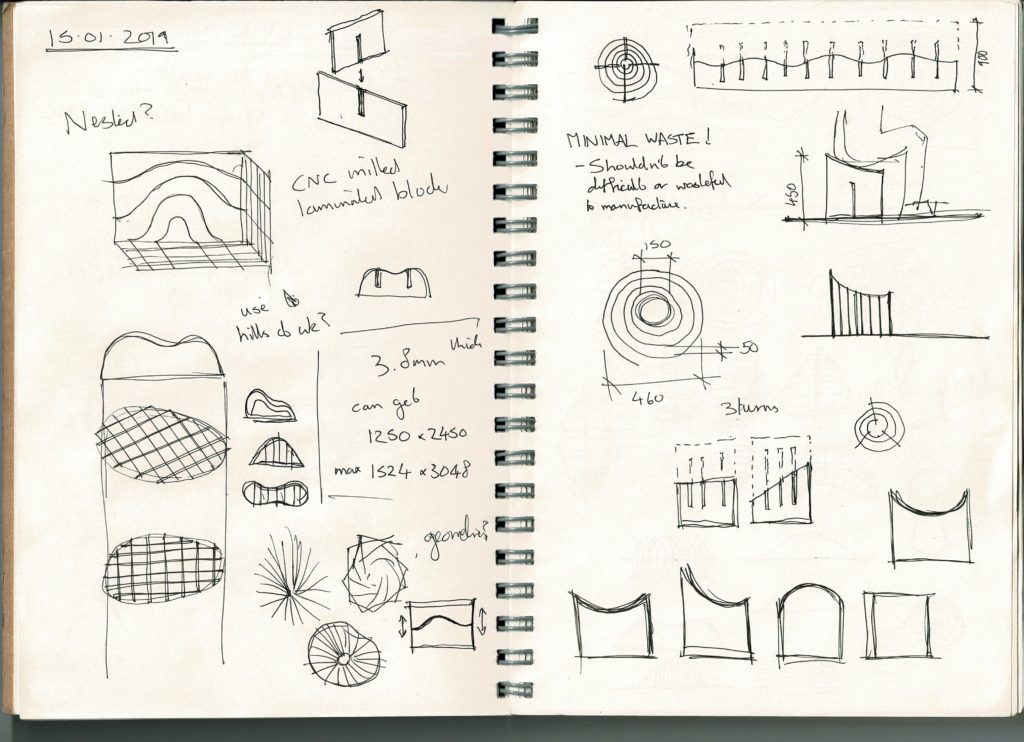

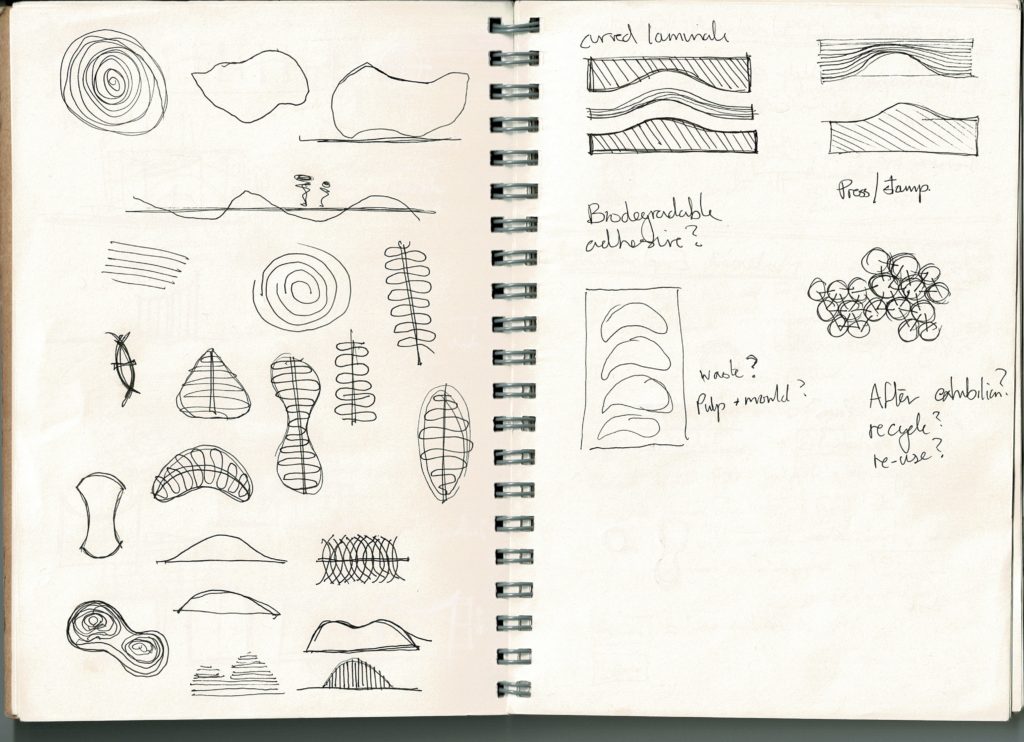

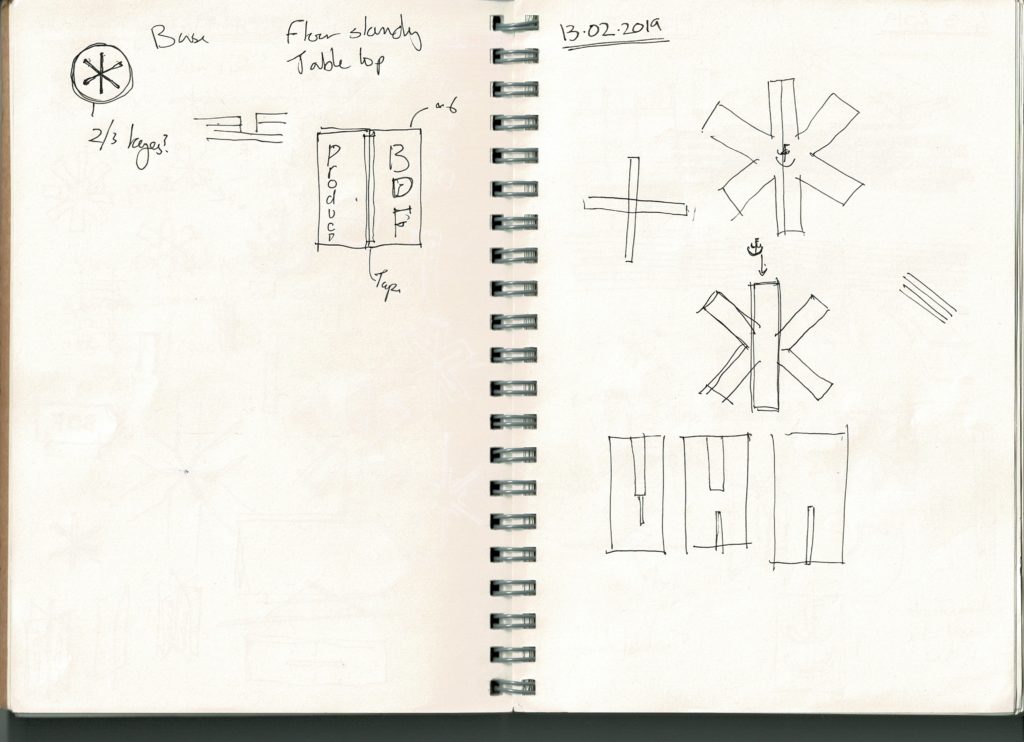

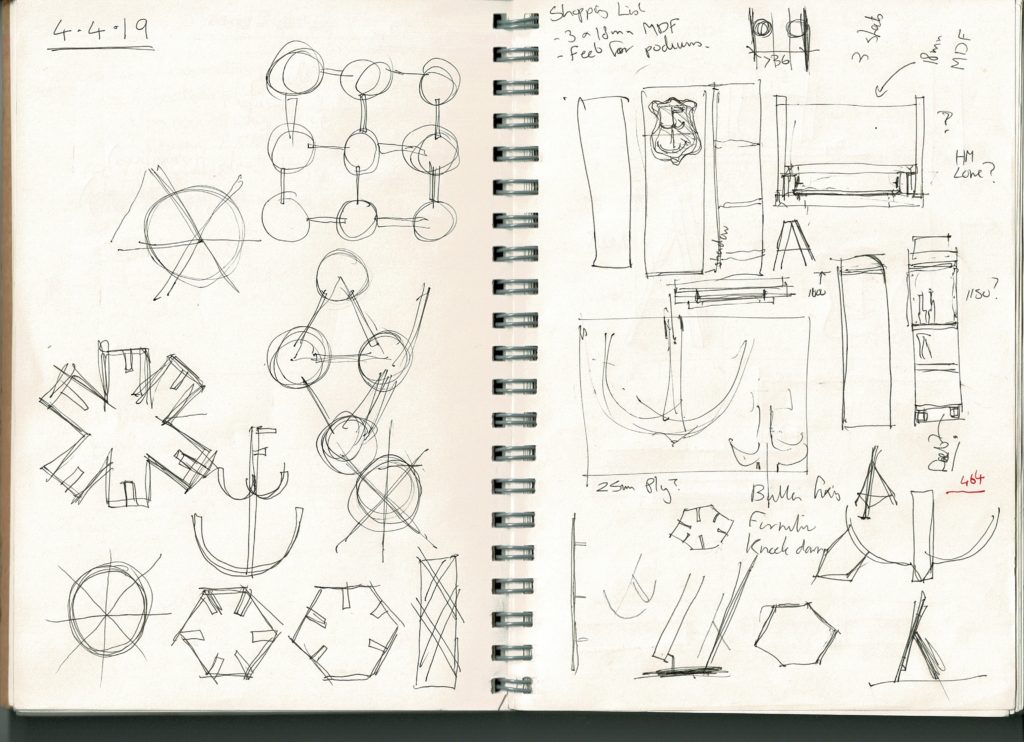

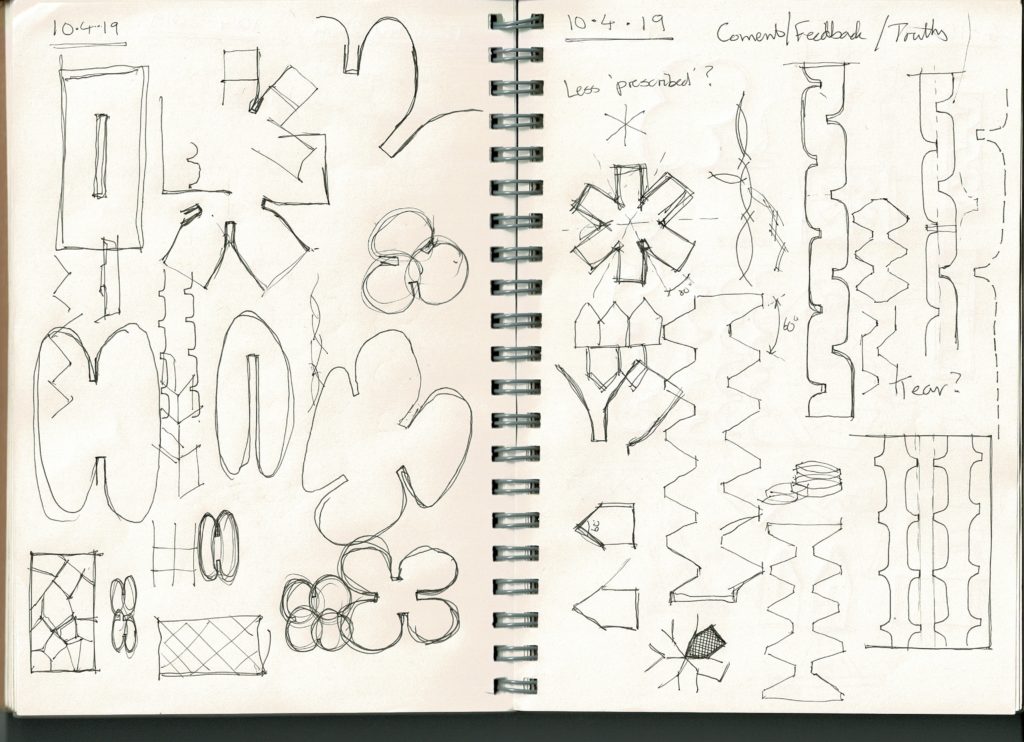

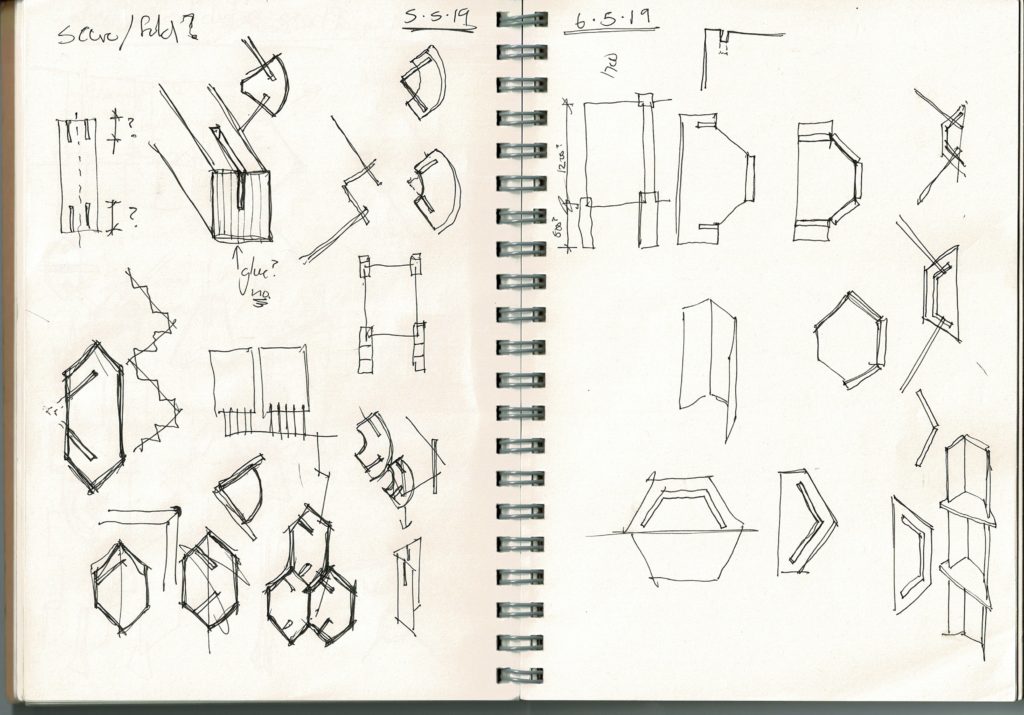

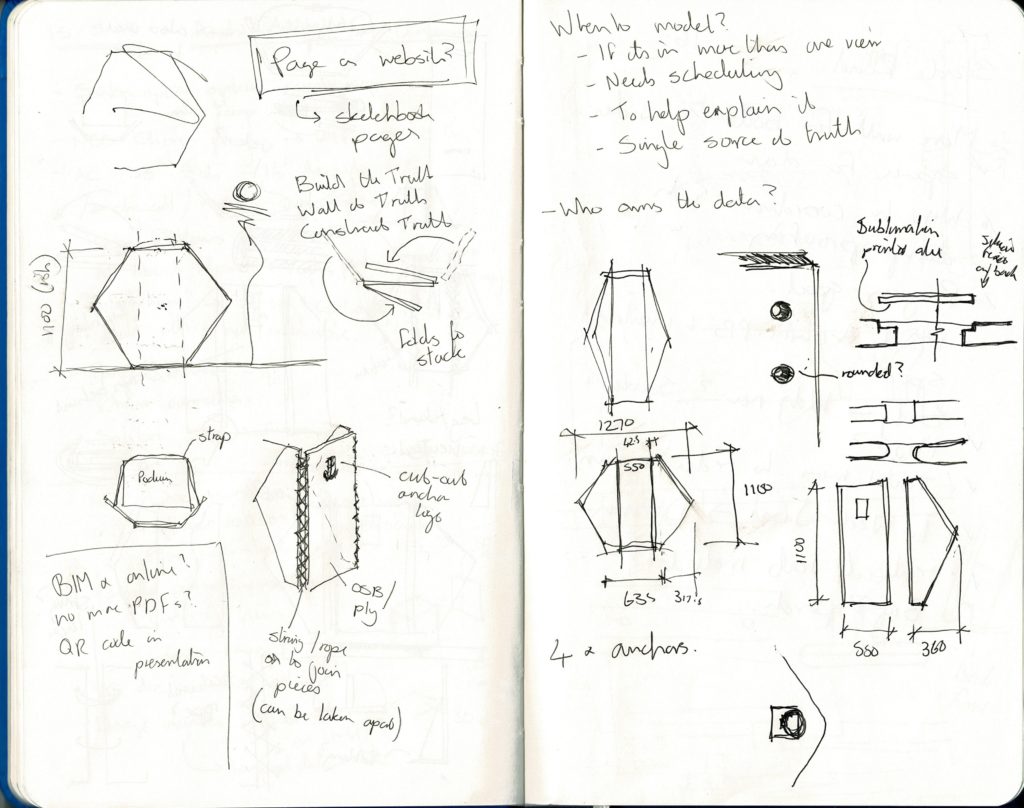

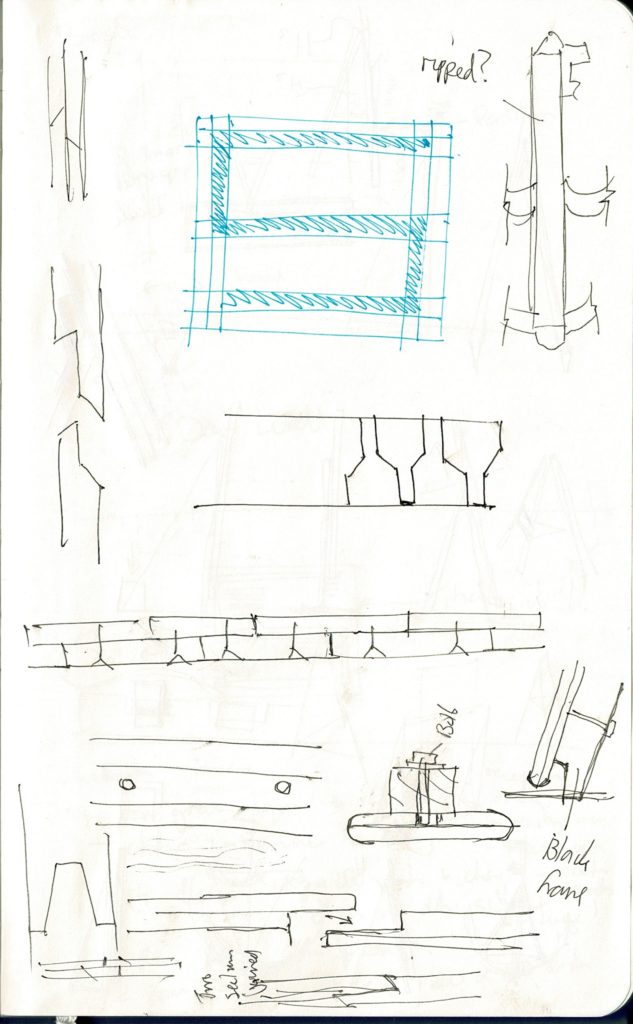

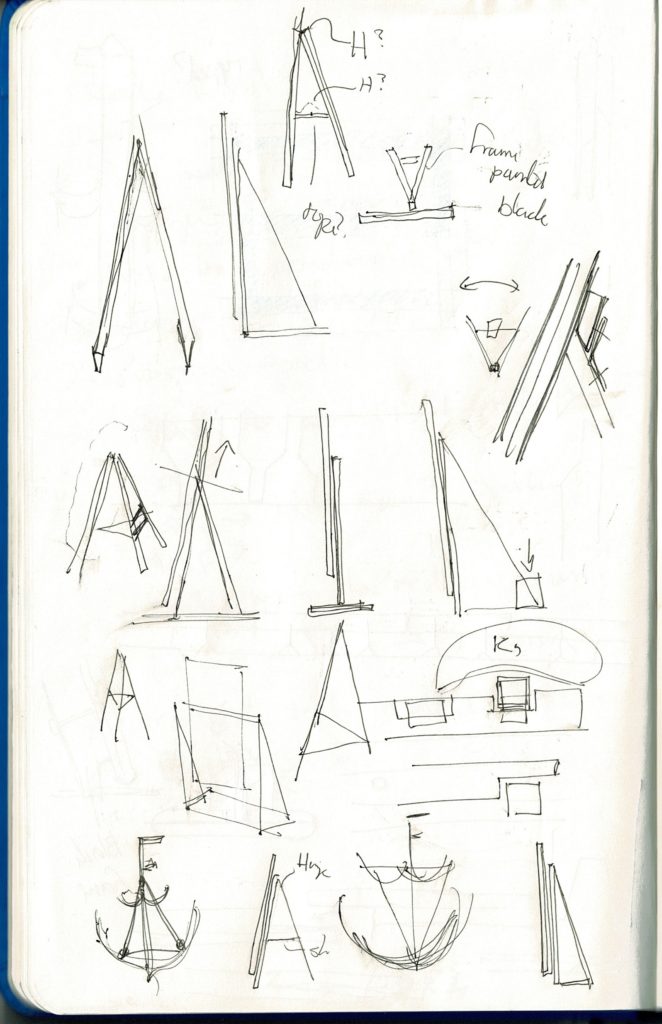

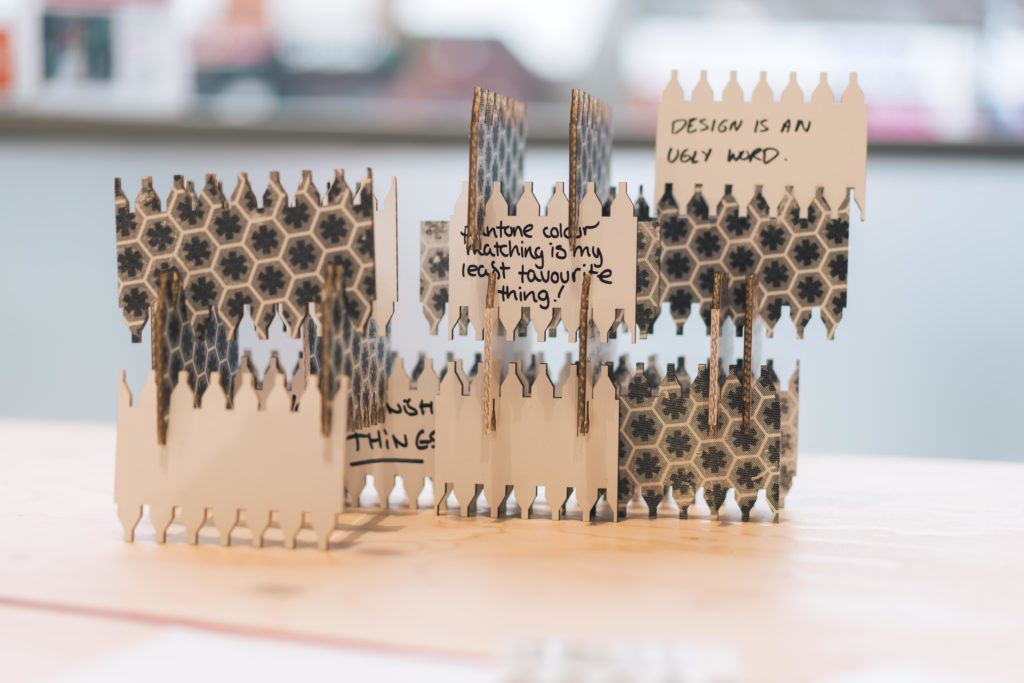

Confession invited participants to anonymously confess their design sins. Wilson describes, “With a conceptual link to confessional booths and the intricate mesh screen between priest and sinner, these confession cards interlock to build an intricate lattice structure. The material used is DISPA®, an innovative corrugated board which is made entirely out of paper and is completely biodegradable.”

Examples of anonymous confessions include, “Design is an ugly word” and “Pantone colour matching is my least favorite thing!” The installation was hands-on, humorous, introspective and sustainable. The development exceeded our hopes in displaying the unique capabilities of DISPA with handmade free-formed interlocking yet fully stable DISPA structures, made by the culmination of participant confessions. It also included an original pattern print by Wilson which displayed its printability and excellent surface qualities.

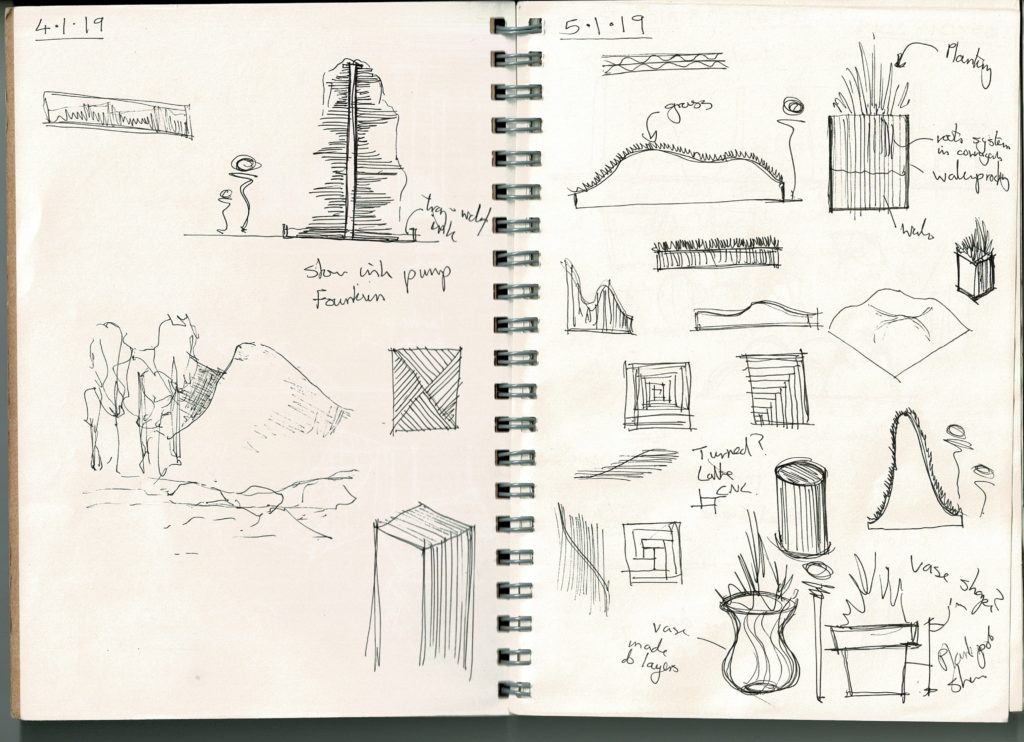

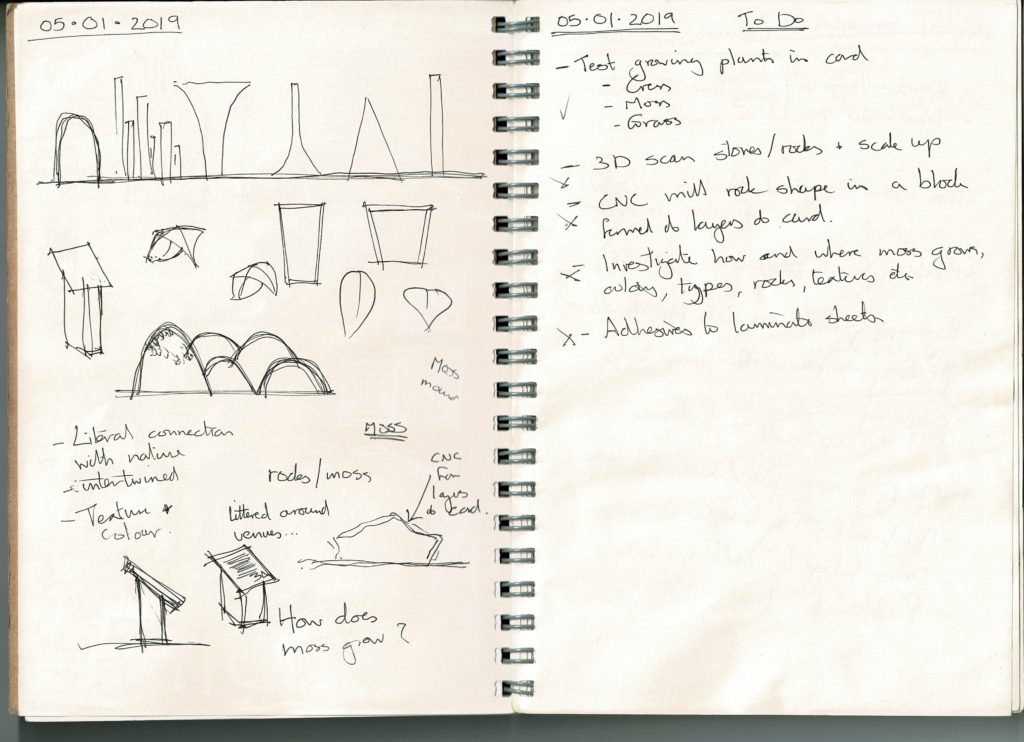

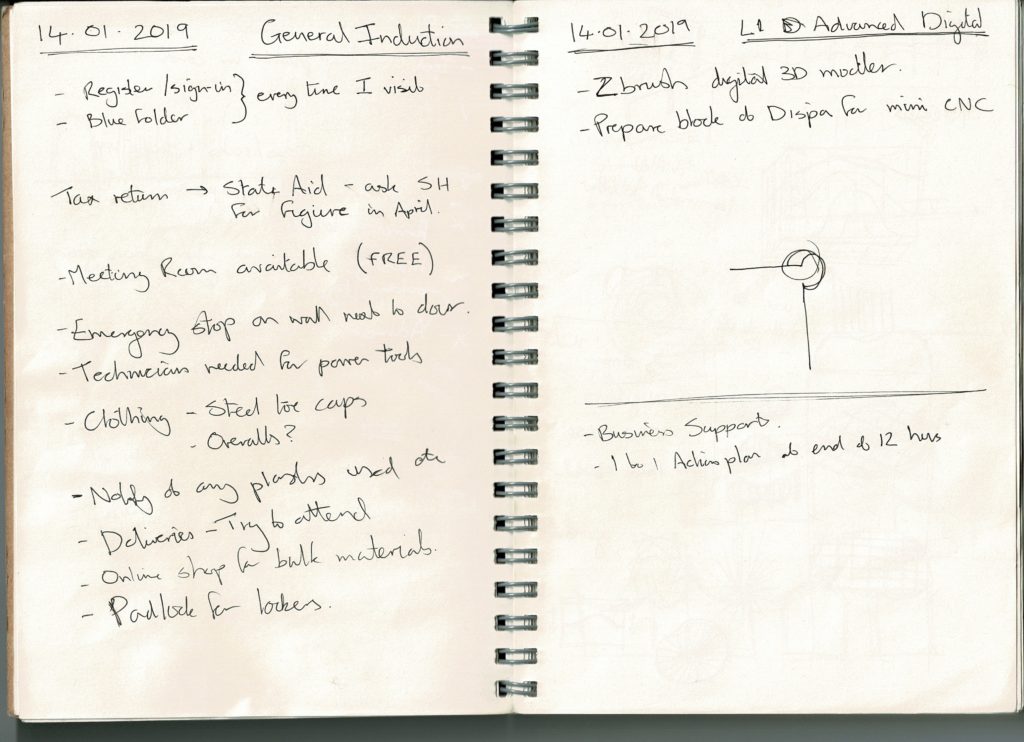

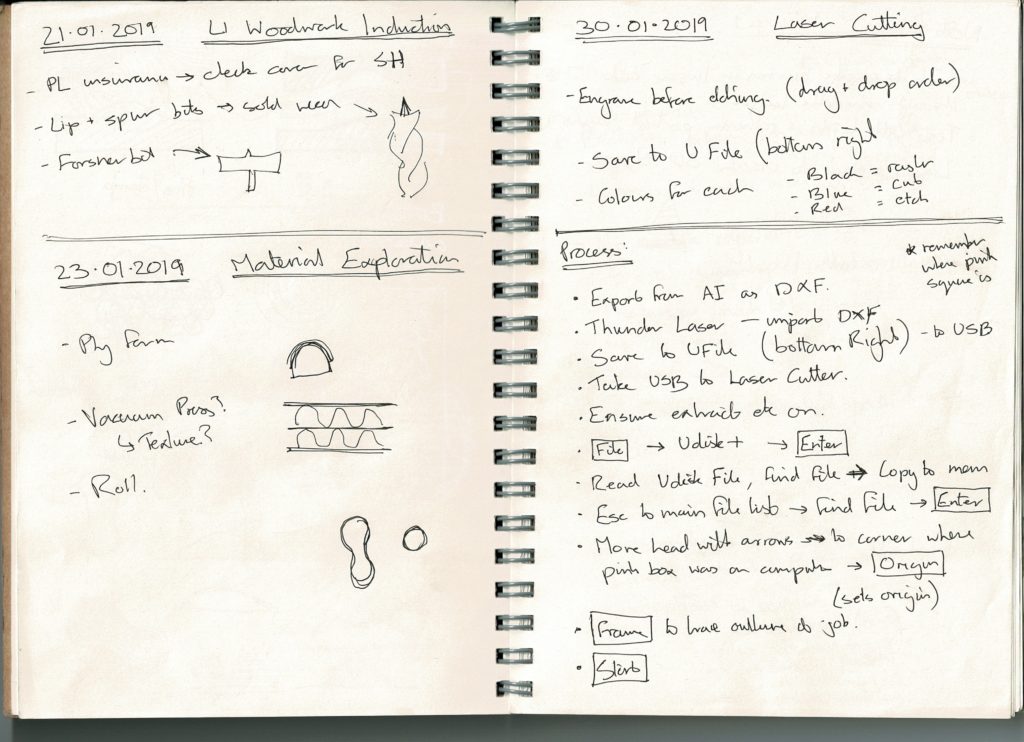

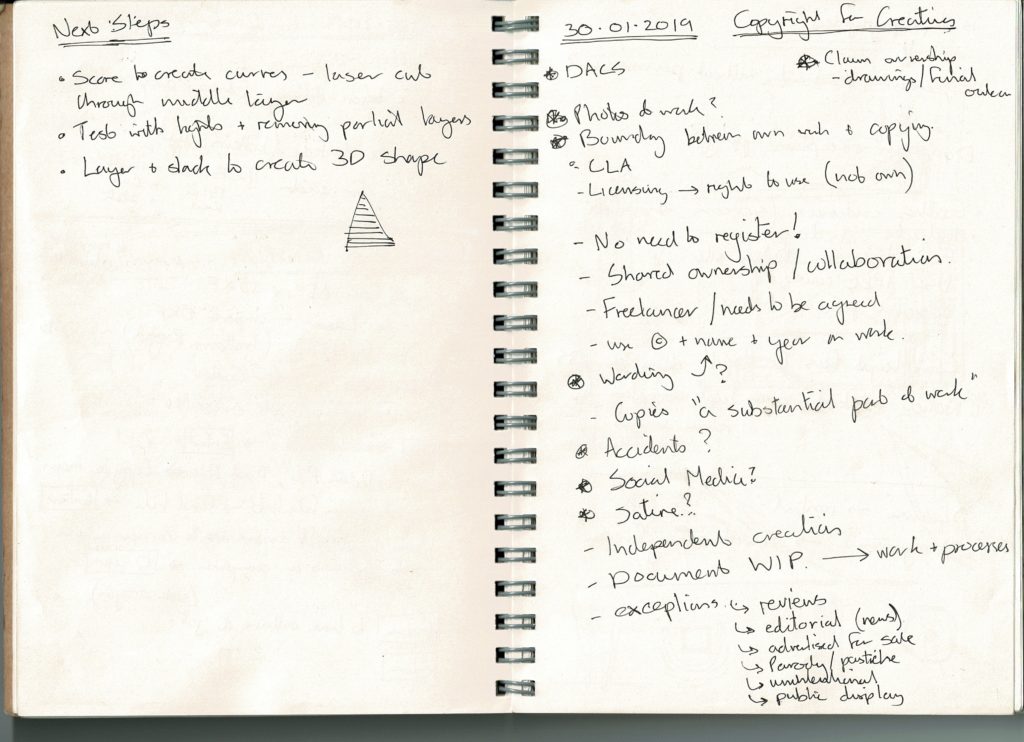

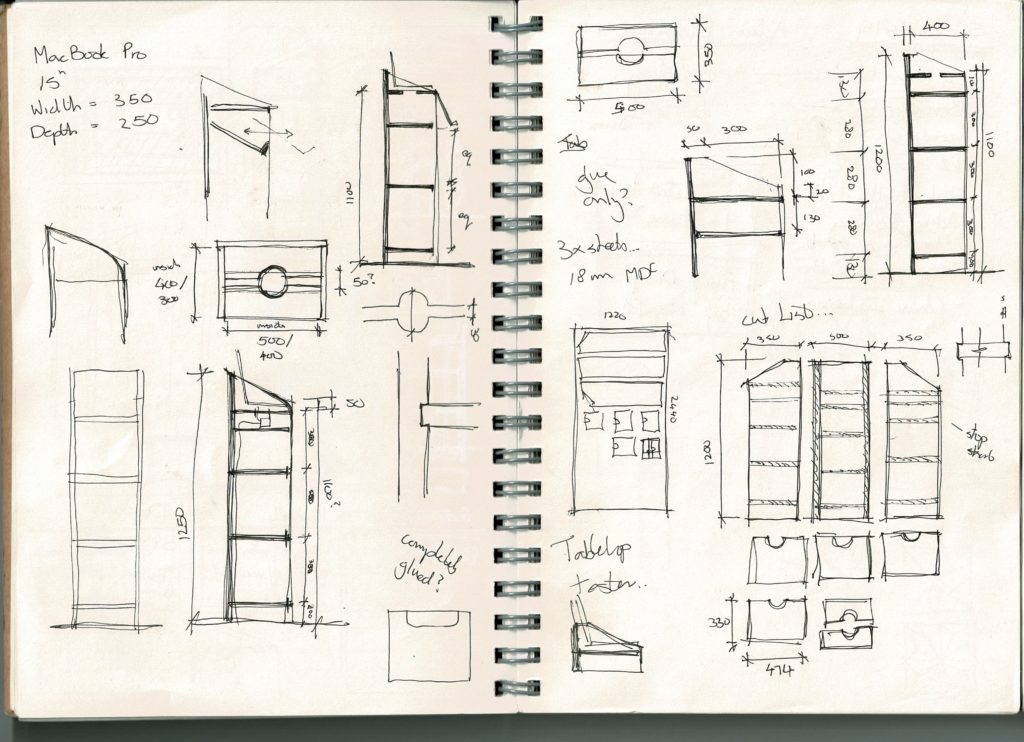

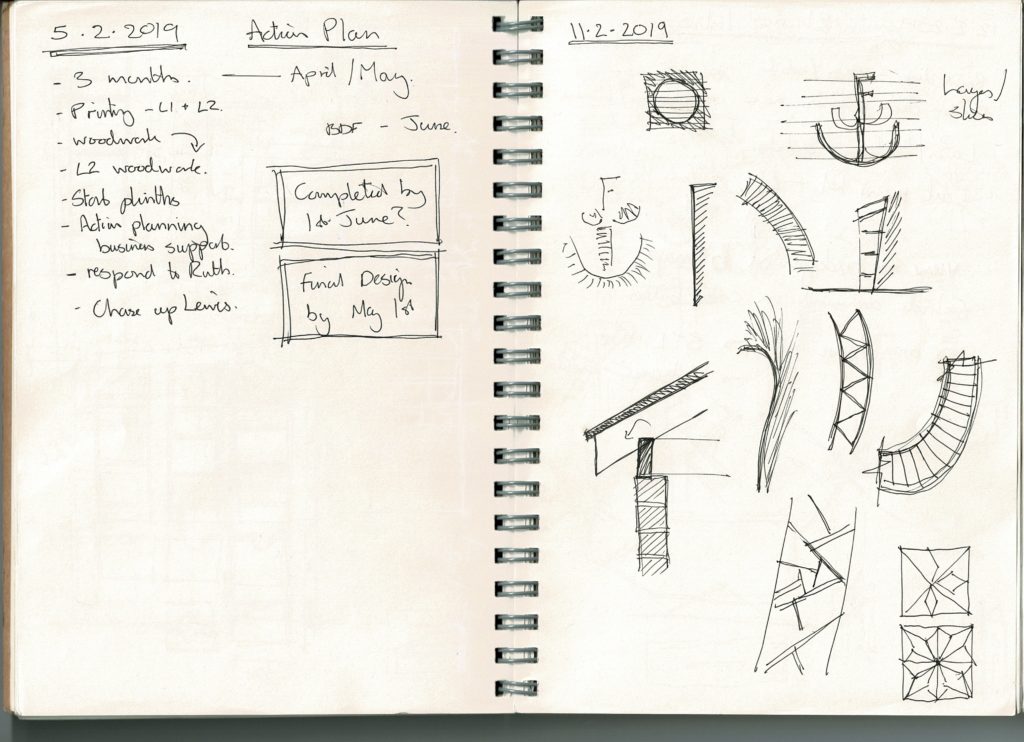

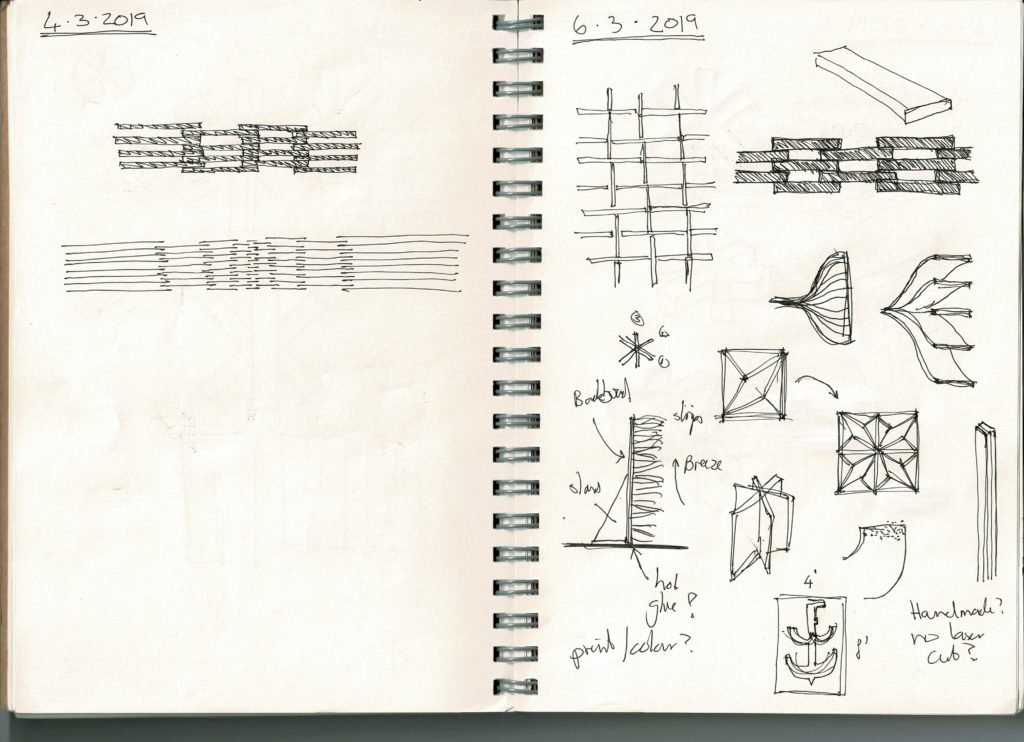

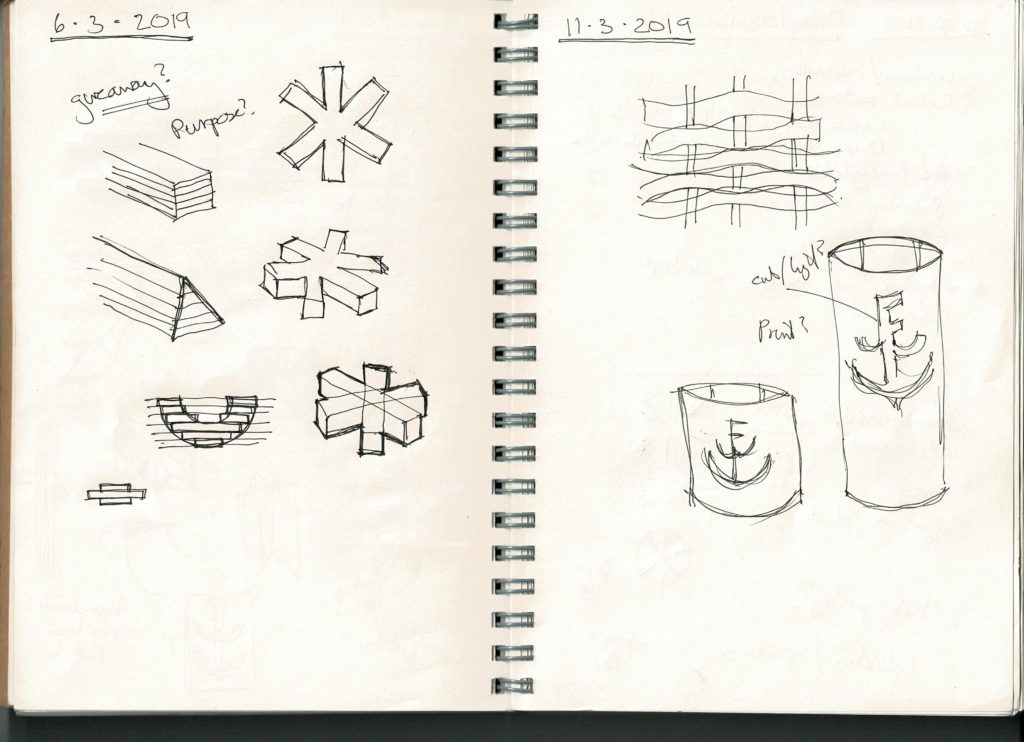

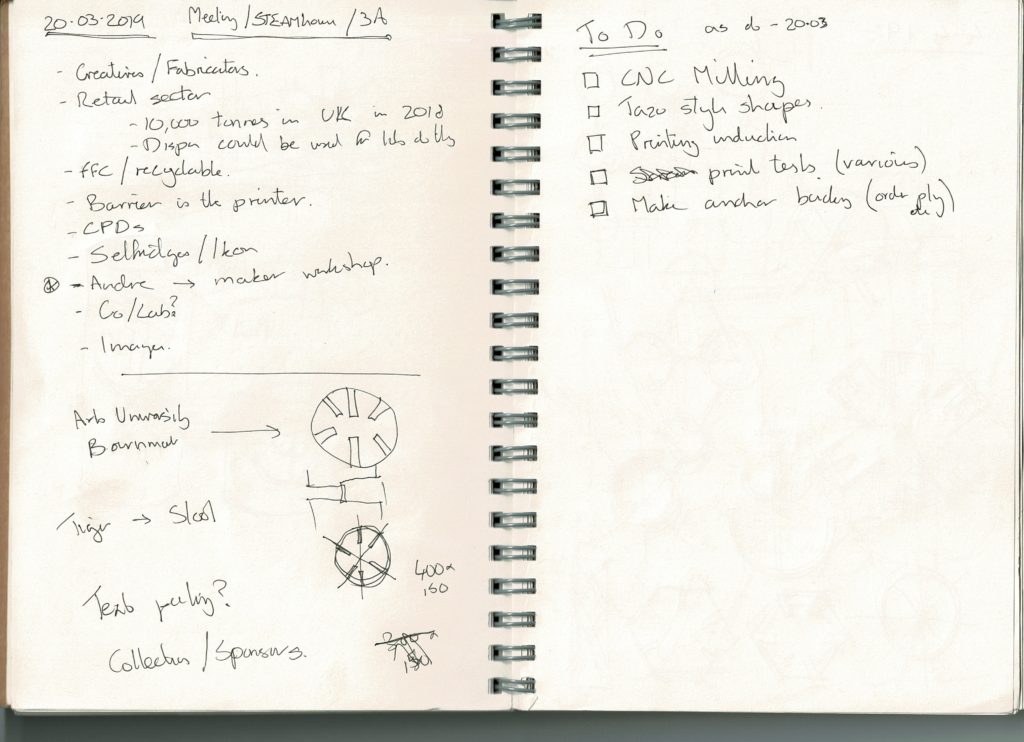

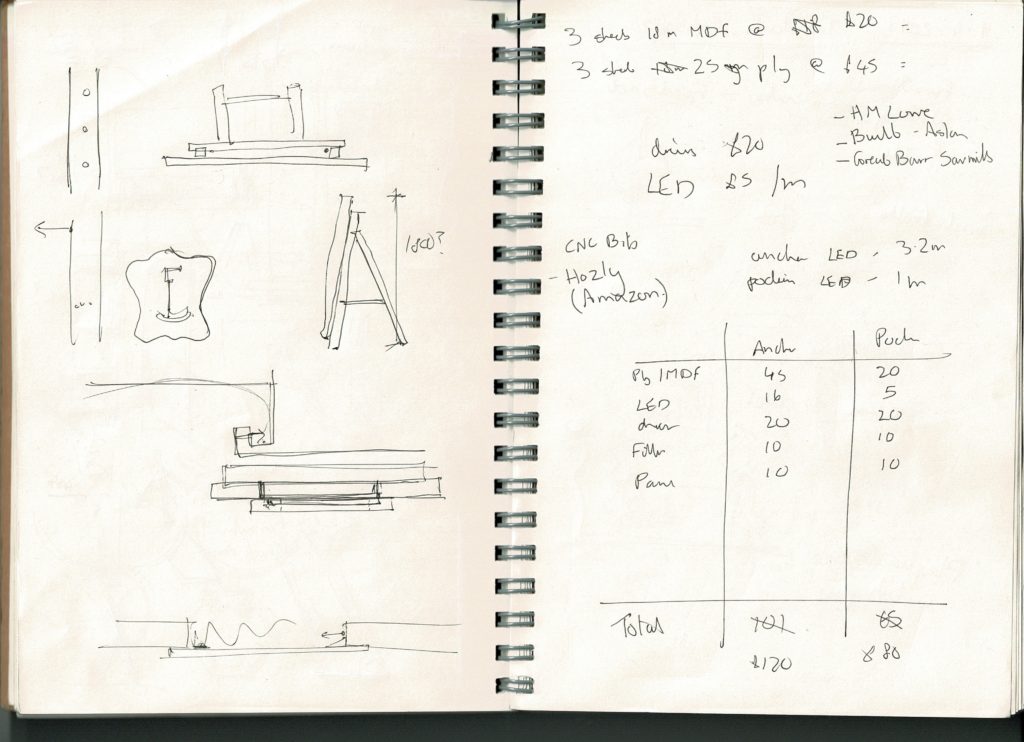

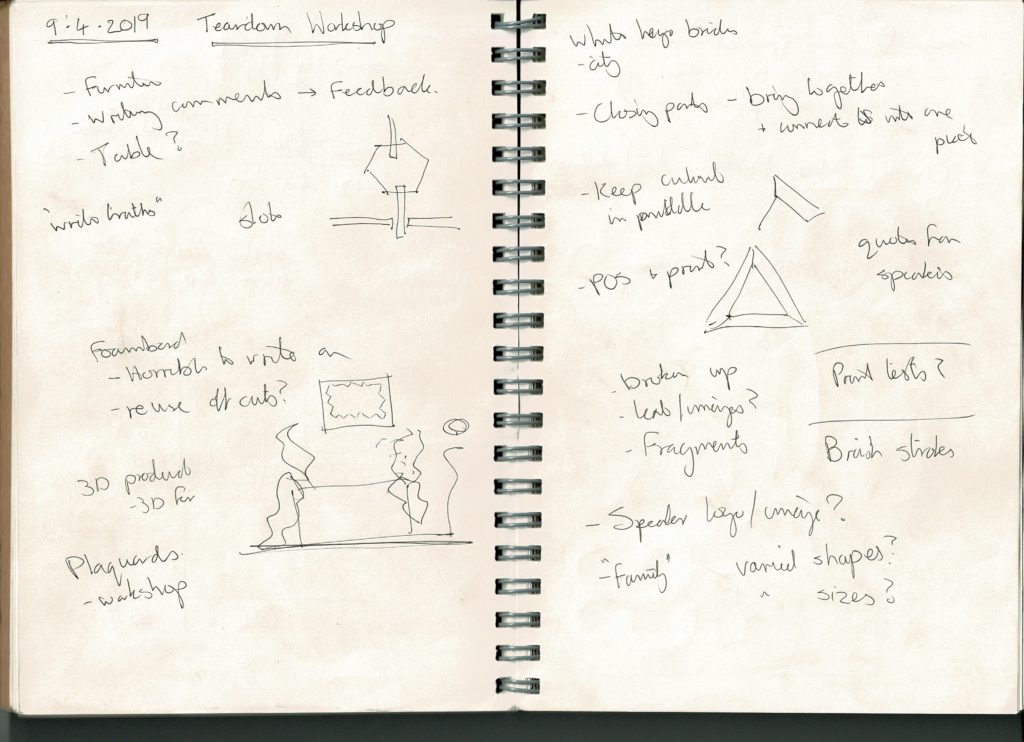

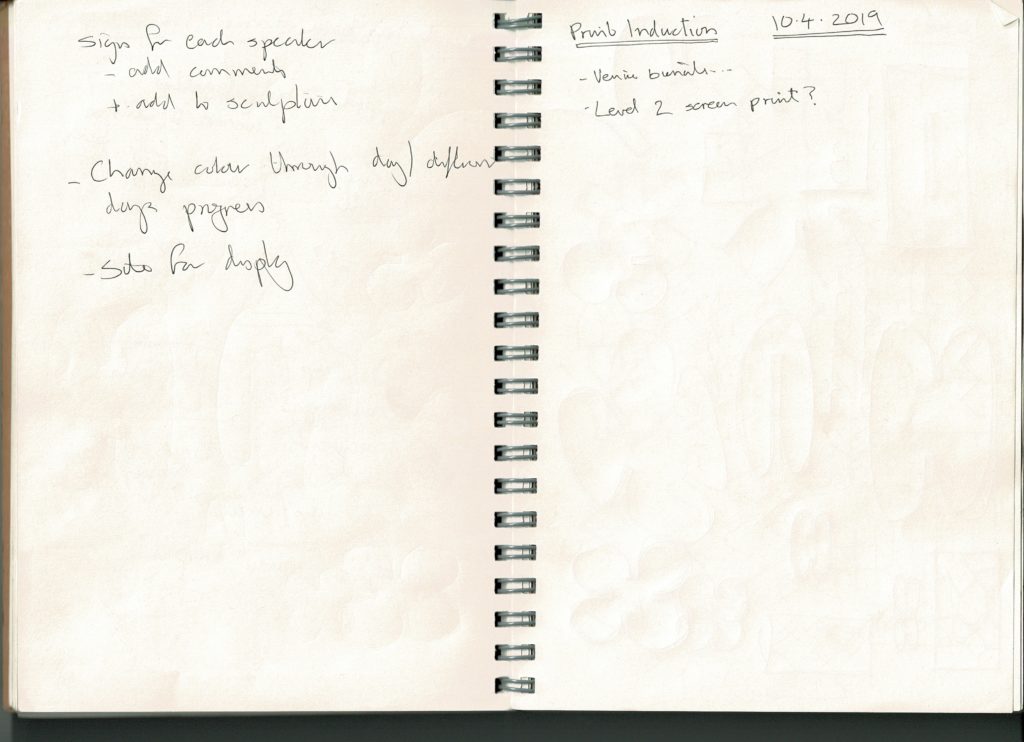

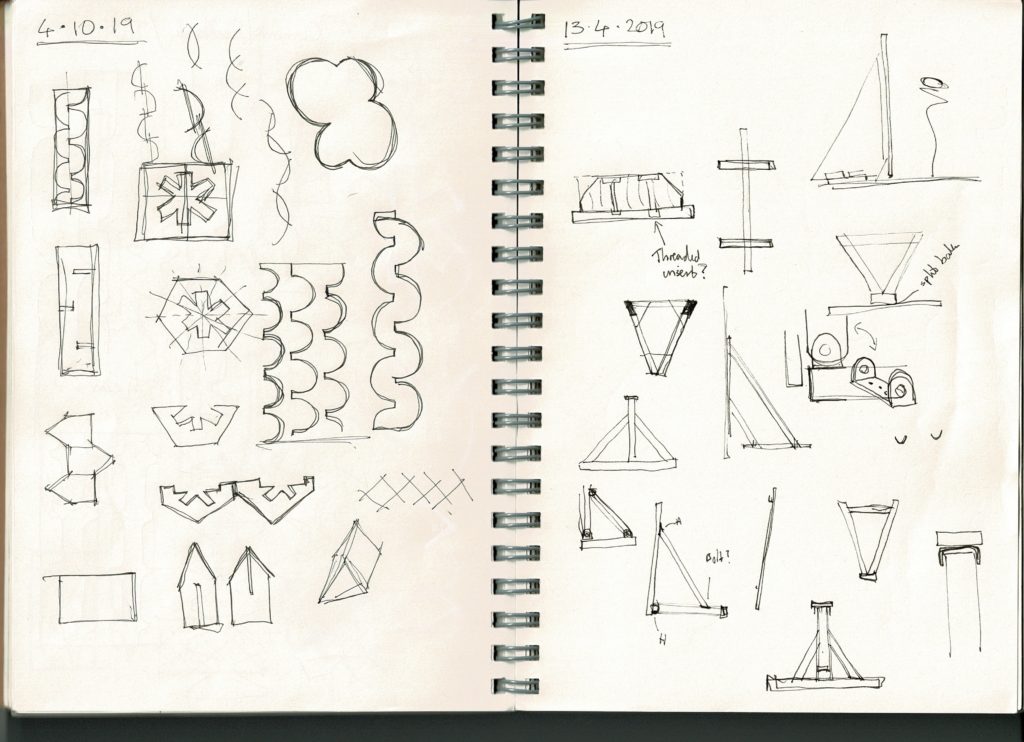

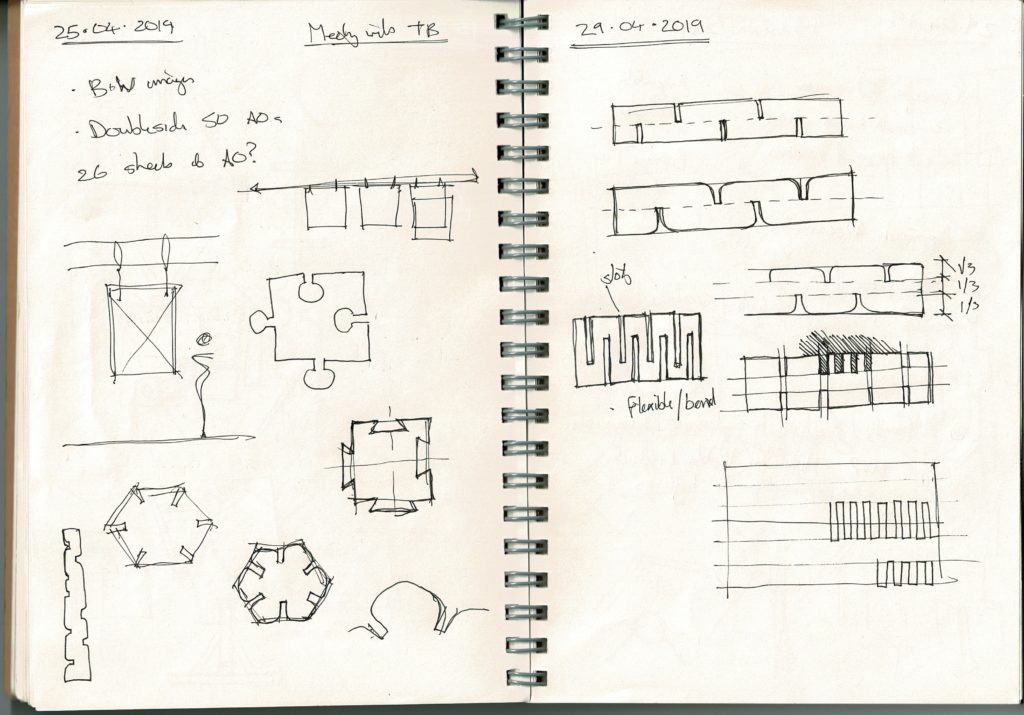

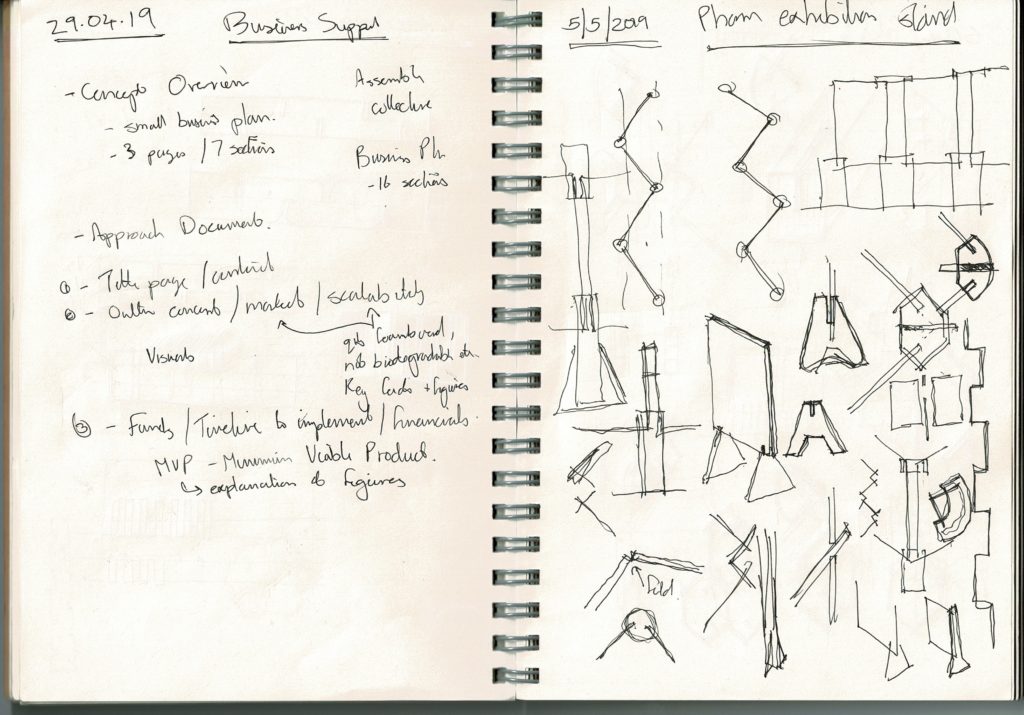

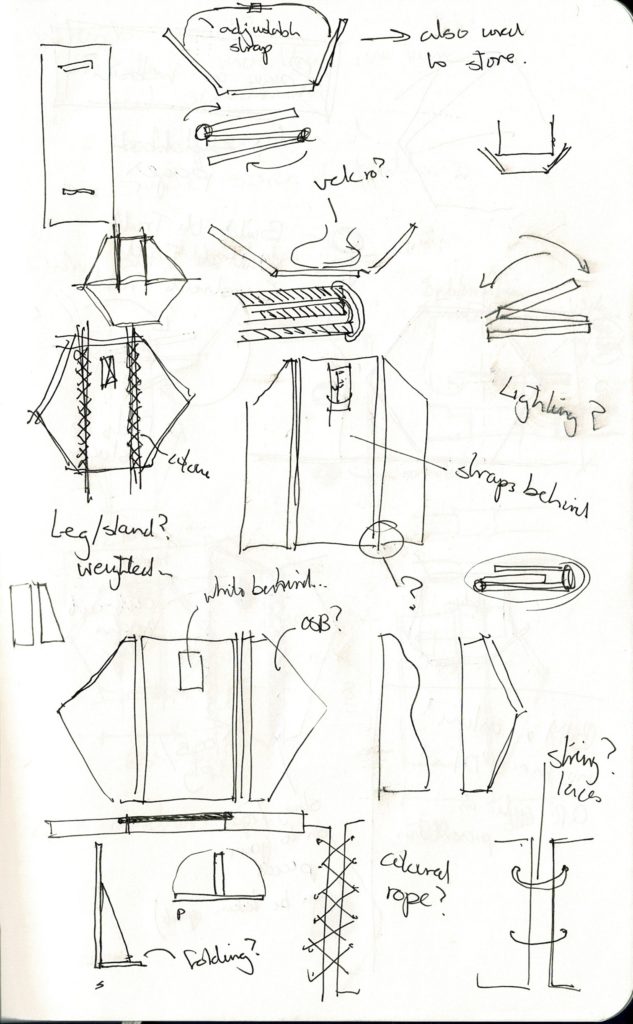

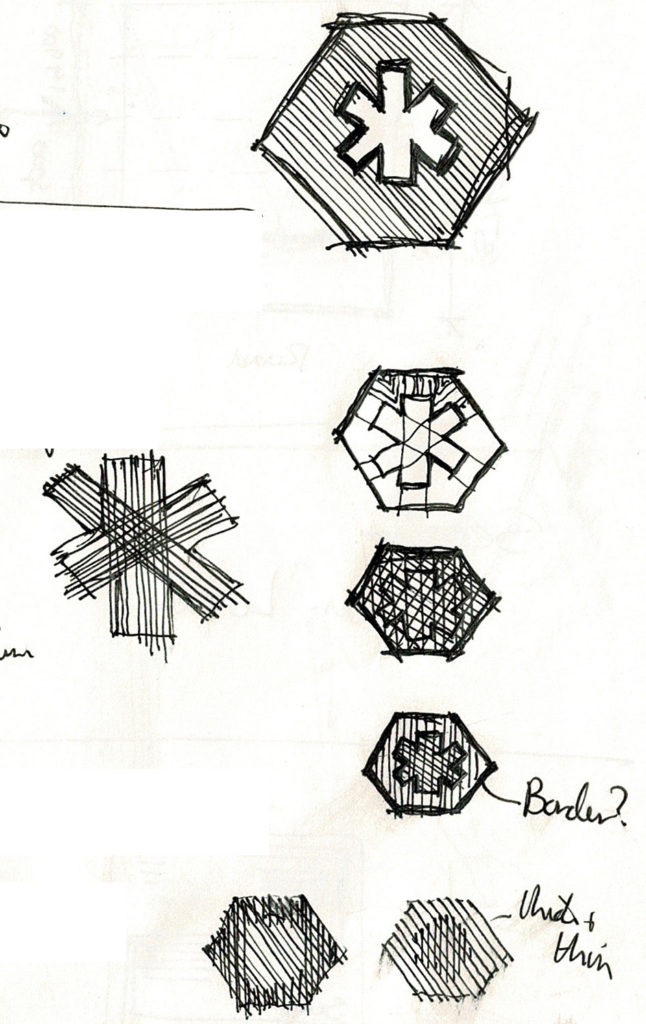

Wilson laser cut DISPA in 3.8mm thickness and insured no material waste. The pattern was screen printed onto large sheets in black acrylic ink before being laser cut. the details of his preparation and execution for the installation are outlined in his intricate development sketches below.